Looks bad? Like I mentioned previously, I am not down and out yet - I am happy that the bearing surfaces are going to be OK on either end of the crank, but if the rusty sludge has got into the conrod bearings then it could be a total loss.

Given that this part weighs a lot, I am not hopeful that ordering a replacement from overseas would be within the budget.

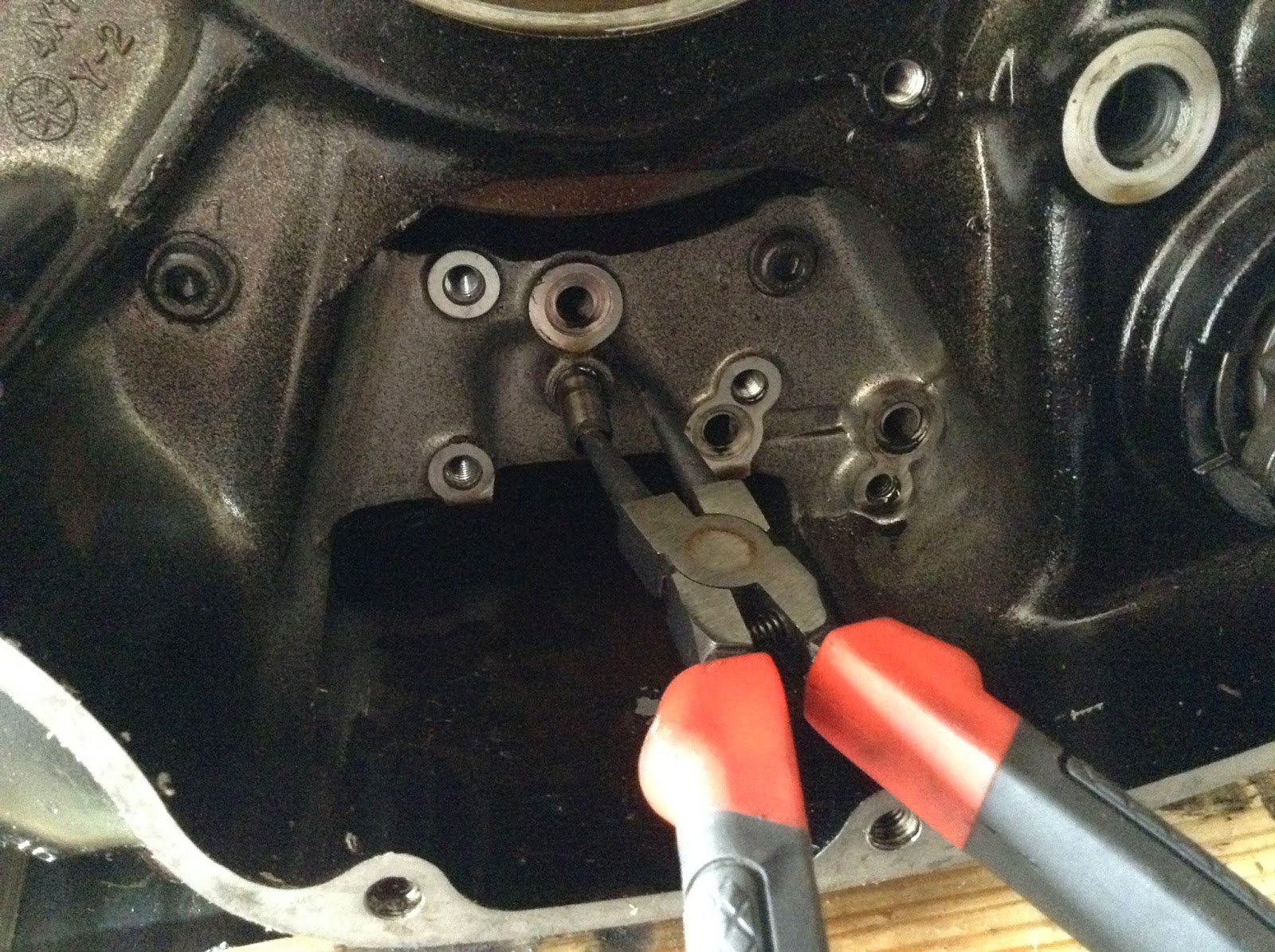

I also noticed this. A solid crack on the piston skirt. Doesn't look new, but it could have been from when I was trying to remove the engine accessories - I had locked the piston against the crank and might have damaged it. Hopefully that's the worst of it - I am expecting the barrel to need a rebore anyway s new pistons and rings are likely anyway.

And as luck would have it the bearing surfaces show wear but not damage! I will have to check the clearances but will do that after de-rusting.

Given that this part weighs a lot, I am not hopeful that ordering a replacement from overseas would be within the budget.

I also noticed this. A solid crack on the piston skirt. Doesn't look new, but it could have been from when I was trying to remove the engine accessories - I had locked the piston against the crank and might have damaged it. Hopefully that's the worst of it - I am expecting the barrel to need a rebore anyway s new pistons and rings are likely anyway.

And as luck would have it the bearing surfaces show wear but not damage! I will have to check the clearances but will do that after de-rusting.